Technology and the Trades

The Sawmill Division at J.D. Irving, Limited has always been at the forefront of technology - from laser scanners and automatic wrappers, to programs that reduce the waste of a log. Now the mills have added augmented reality to their arsenal.

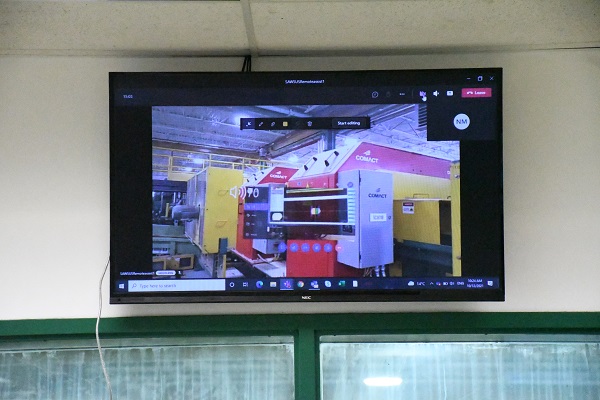

Microsoft Hololens has been deployed at all sawmill sites, providing the maintenance team with a tool that allow them to project analytics and reporting into an operating space.

"With the hololens we save time and resources in trouble shooting with the ability to take images, manuals, and drawings directly into the field with the flick of a wrist," says Neal Mercer, Electrical Supervisor at the Sussex Sawmill.

Most of the units in the mill send their output information to a computer that sits in a control room. In the past, when a unit was being worked on, the team would have to travel back and forth between the unit and control room to measure progress. With the Hololens technology, analytics follow the maintenance team around the mill as they work on various pieces.

Hololens allows multiple people to watch or assist without crowding a small space. As a Microsoft technology, the wireless glasses work seamlessly with Microsoft Teams. A camera on the front of the headset not only lets Teams meeting participants see what's happening through the user's eyes, but integrated microphones and speakers allow for conversation.

This game changing feature allows for people to assist with projects without being present, a huge concern given recent travel restrictions. Augmented reality has lead to less downtime at the sawmills, allowing production to continue much faster than in the past.

Learn more about the Sawmill Division at jdirvinglumber.com